Vinci et al found that sic contents over 15 vol in a zrb 2 sic matrix ensured the formation of a homogeneous protective borosilicate layer over the sample that minimized c f degradation and burnout during 1 minute oxidation tests at 1500 1600 c.

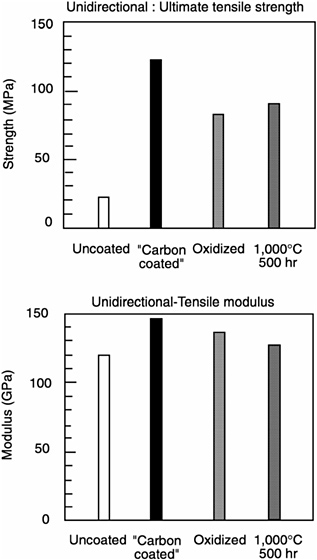

Pyrolytic carbon coating ceramic matrix composite.

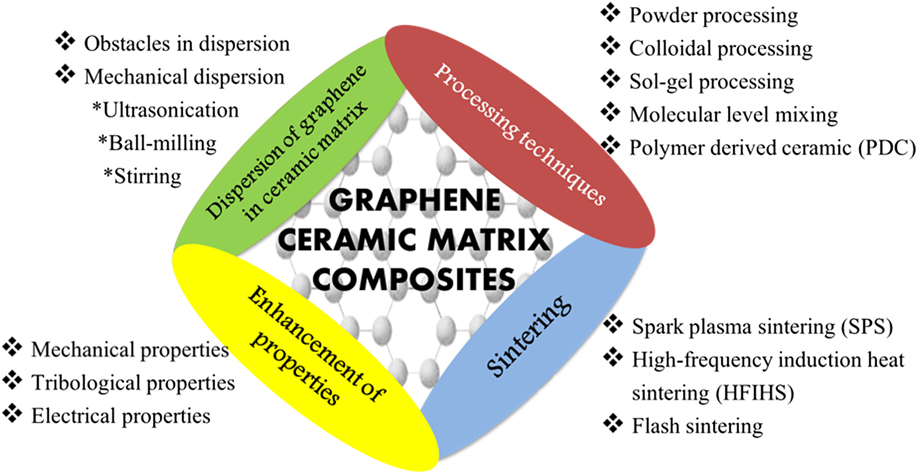

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

Silicon carbide ceramic matrix composites coi ceramics inc.

Then sem xrd and other methods were used to test the microstructure flexural strength fracture toughness and static.

Ceramic matrix composites cmcs are a special type of composite material in which both the reinforcement refractory fibers and matrix material are ceramics.

In this paper c f sic zrc c f c sic zrc composites which the pyrolytic carbon pyc coating with the thickness of 0 1 μm 0 3 μm and 0 5 μm were prepared by chemical vapor deposition cvd process combined with precursor infiltration and pyrolysis pip process.

32 pyrolytic carbon pyc coatings have also been shown to protect c f from processing.

At lower heat treatment temperature htt 1500 c composites with high strength.

Additionally the fibers used for fabrication ceramic composites by lsi should be protected from the highly reactive liquid silicon by a.

Introduction c arbon fiber reinforced composites with ceramic cmc carbon cfc or metal mmc matrix are interesting materials for many applications e g in the field of the automotive industry.

The ceramic fibres were coated with thin layers 100 nm of pyrolytic carbon to prevent diffusion between fibre and glassy matrix.

The introduction of nextel 440 fibres for reinforcement tasks in glass matrix composites has been studied.

The resulting ceramic matrix composite cmc materials have a unique combination of properties.

3 1 2 mechanical properties of composites with pyrolytic carbon matrix.

This process is versatile and robust well suited for the fabrication of complex components.

In some cases the same kind of ceramic is used for both parts of the structure and additional secondary fibers may also be included.

Carbon fibers are the optimum reinforcement for many composite systems and are the constituent of choice for hot structures because of their.

To provide debonding coating of pyrolytic carbon c or hexagonal bn is deposited over the fiber surface.

The use of coatings to protect carbon fibers and carbon carbon cc composite from chemical attack at elevated temperatures is important for the development of lightweight structural materials for use in advanced aircraft and aerospace applications.

In c cs with pyrolytic carbon tensile strengths in the fiber direction of 1000 1400 mn m 2 have been reported which correspond to 80 90 of the fiber properties translation 62 63.

The main reason for this is a remarkable weight reduction.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.